social corporate responsibility

Environmental Sustainability

The

Cremonini Group has pledged to safeguard the environment and believes in the

importance of encouraging sustainable development, so as to keep under constant

control the consumptions and environmental impacts derived from its own

production processes and services offered.

ENVIRONMENTAL SUSTAINABILITY OF THE PRODUCTION SECTOR

To promote environmental sustainability in the production sector, the Group follows three main directives:

- Energetic

efficiency and the self-production of energy (cogeneration);

- The

improvement of a product’s lifecycle (LCA – Life Cycle Assessment);

- The

use of renewable resources and the recovery of waste and by-products (biogas

production).

Cremonini is at the forefront in the sector of energy use from renewable sources: through the subsidiary Inalca it has created a Biogas plant for the production of energy from renewable sources constituted primarily by biomasses and by-products of slaughtering.

Kyoto Protocol

After having adhered to the Kyoto protocol between 2007 and 2010, Inalca has distinguished itself by having reduced the CO2 emissions and for having improved the energy efficiency of its own production by 41.6%*. For this commitment it was rewarded by COOP for being among the best suppliers of the supermarket chain. (*validity of data controlled by Veritas Bureau Italy).

An integrated and sustainable beef industry

The Cremonini Group, through Inalca, is one of the few Italian companies to control the entire production chain, from breeding, to meat processing, up to the distribution of the finished product. Today it is the star of a new model of sustainable production based on an integrated management of the supply chain, wholly made in Italy and replicable in diverse countries around the world.

The meat chain production is composed by the following elements: feed production, breeding, slaughtering, meat processing, distribution and conservation. In the model developed by Inalca all these elements are linked to each other and managed according to a common goal that, in addition to ensuring full economic efficiency, permits to have:

- certainty

in controls to guarantee quality and product safety;

- transparency,

product information that is complete, accurate and accessible by the consumer;

- environmental

protection, with optimisation of resources, minimising environmental

impacts, maximisation of recovery activities and valorisation of waste and

by-products;

- cost

reductions and fair remuneration for all the operators;

- animal welfare.

The "short" beef chain

Some data can illustrate the benefits of an integrated supply chain. For example, the location of processing plants, concentrated in areas where 80% of the cattle is present: the "short" supply chain guarantees the respect of animal welfare and the reduction of CO2 emissions from transport.

The valorisation of products

Regarding products, the enormous production capacities combined with the sales network and the distribution infrastructure on a global scale, allow Inalca to valorise at best each cut of meat and every one of the 3,000 parts derived from the processing of bovine, placing each individual product in markets where traditions and styles of use allow the maximum valorisation.

Green Energy: INALCA self-produces 100% of its energy

From the energy saving point of view and the use of renewable resources, Inalca self-produces more than 70% of its energy needs through industrial cogeneration and the production of green energy (biogas) obtained by processing waste. This means that in recent years Inalca has steadily reduced emissions despite increased energy requirements.

Recycling waste

99% of waste is recycled and over 7,000 tonnes/year of compost are produced and recycled in agriculture as fertiliser.

Bovine are generous animals

The integrated process allows Inalca to valorise at best the hundreds of products resulting from bovine processing: from bovine not only the meat is used, but also the skin, bones, cartilage, fat, rumen contents, up to livestock sewage.

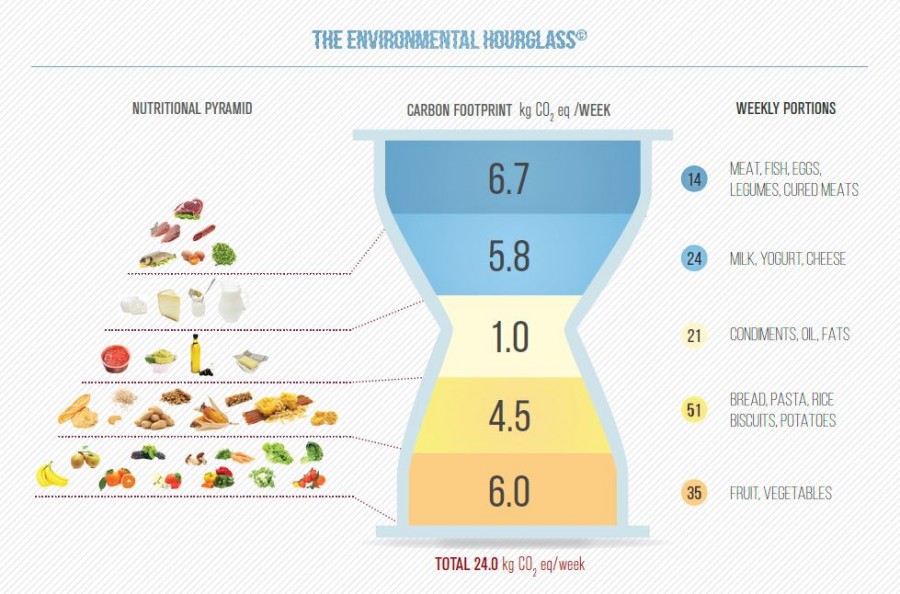

The environmental hourglass: a balanced diet is also sustainable for the environment

The possibility of controlling the entire

beef production chain, has permitted for the first time to gather all the data

needed to evaluate the environmental impact of meat production in Italy, making

a fundamental contribution to the development of the model of the Environmental Hourglass proposed

officially as a contribution to the Charter

of Milan.

To date the carbon footprint of the

meat industry has been assessed in absolute terms (CO2 emissions per unit/kg of meat). Now, starting with the food

pyramid, the representation of the Mediterranean diet proposed by CRA-NUT and

today considered by world scientists a point of reference in a healthy and balanced diet, the environmental

impact of individual foods were calculated, taking into account the amount and number of weekly portions

recommended.

The result is that the products which have a

greater impact are those that, according to a balanced weekly diet, must be

consumed in a reduced quantity and frequency compared to all other low impact

foods, which on the other hand should be consumed in quantities far higher and

more frequently.

The most important aspect that emerges from

this representation is such that, in a

balanced weekly diet, the carbon footprint of foods rich in protein (meat,

fish, eggs, beans, sausages) is decidedly comparable to the impact

generated by foods of plant origin

(fruit, vegetables). In fact, if taken in the right amounts, the various foods have an

"environmental load" that is very similar, distributed evenly

throughout the hourglass.

This reinforces the view that following a nutrition coherent with the Mediterranean model is useful not only for reasons of ones own health, but also for those of the environment.

The environmental hourglass represents the weekly carbon footprint of a person that eats according to the instructions of the Mediterranean diet.

PLEASE WATCH THE VIDEO TO DISCOVER MORE - https://www.youtube.com/watch?v=ngJqmu1ixCg

ENVIRONMENTAL SUSTAINABILITY OF THE DISTRIBUTION SECTOR

Green products

In the distribution sector, more than 2,000 referenced Green Products have been introduced to catering companies. MARR has in fact increased the percentage of eco-friendly products which meet the environmental criteria of reference, with the aim of implementing a "Green" purchasing policy on behalf of its customers.

Reduction of CO2 emissions

Furthermore, thanks to an exclusive order management software, that optimises logistic processes related to the delivery of products to its customers, ensuring through a full load a reduction in mileage and travel time. Some of the transport vehicles used are of low environmental impact.

Recyclable packaging

Lastly, 100% of the packaging used by MARR for

its activities is made up of recycled material.

ENVIRONMENTAL SUSTAINABILITY OF THE CATERING SECTOR

Also in the catering sector, Cremonini is committed to environmental sustainability: recyclable or biodegradable materials are used and 100% of the points of sale recycle waste in accordance with the instructions of the local borough.

Energy saving

These projects have also been launched:

- Sines Power Project: A particular system of tension reduction has been installed in 33 premises that allows a saving in electricity consumption of around 10%. The project will also be extended to another 66 premises.

- Photovoltaic Project: Photovoltaic plants have been built to meet the energy needs in all Roadhouse Grill premises and Chef Express service areas with suitable concessions.